Are you planning to purchase a high-frequency (HF) welding machine but wondering whether to choose the Fiab 860 or the Fiab 960? Both models are high-quality machines for welding materials such as PVC, TPU, PU, or coated fabrics. Although they have much in common, they differ in power, size, and purpose. In this article, we explain when it’s best to choose each of them.

How to make the right decision?

Production with high-frequency welding machines is never “the same” – each project is essentially individual, tailored to the specific needs of the user, even when we’re talking about serial models.

Selecting and configuring an HF welding machine is similar to choosing a car:

It happens that needs are so unique that our R&D department designs solutions specifically for one investor.

Translating this to the automotive industry – it would be like creating a special delivery van with refrigeration and tool storage with additional batteries maintaining cooling around the clock.

Without considering all these factors, even the most experienced advisor – both in the HF industry and in automotive – will not be able to indicate the optimal solution. Therefore, to choose a model perfectly suited to your needs, it’s worth first answering a few key questions:

We have answers to the first two questions. However, the conclusions drawn from them do not yet lead to a clear choice, because all the previously mentioned products can be manufactured on both the Fiab 860 and Fiab 960 models.

Therefore, we move forward and ask:

Even these answers may prove insufficient, because in the case of materials with a weight of, for example, 250 g/m² to 800 g/m², both welding machines will work well.

Therefore, let’s go a step further:

Do you have enough space?

Consider whether in the coming years you plan to produce only one type of product or gradually develop the offer with additional projects, both of the same and larger size.

Do you need a solution dedicated to one specific activity, or rather a universal machine that will provide flexibility in case of unforeseen needs?

Or perhaps you’re planning to move production to a larger hall or build an additional hall along with expanding the machine fleet?

How does the model I’ve chosen fit into the vision of the future?

If you still have more than one welding machine to choose from, the investment budget should decide.

Let’s assume that you can get from point A to point B with both a cheaper and a more expensive car – the difference, however, lies in travel comfort, which affects, among other things, the number of stops, both for refueling and rest, as well as the speed of the entire journey.

It’s similar with high-frequency welding machines.

Just as the main task of a car is to move from point A to point B, the main task of a welding machine is to weld material.

The most important question is: do you now care about a quick return on investment with slightly slower production, or do you prefer maximum efficiency and the implementation of a greater number of contracts, even if the return will be long-term, with the prospect of greater revenues in the future?

The investment should be proportional to the expected return, so that the value of invested funds is fully justified in the context of company development.

Of course, in this consideration, we omit extreme and rare cases that require the selection of a special machine – in analogy to the automotive industry, this would be, for example, a fire truck or ambulance.

Dedicated, non-standard, and individually designed machines are a topic for a separate article.

When we already have a picture emerging from the conclusions of previous questions and we know exactly what we need, we can proceed to selecting the appropriate model.

In this article, we will focus on comparing the Fiab 860 and Fiab 960.

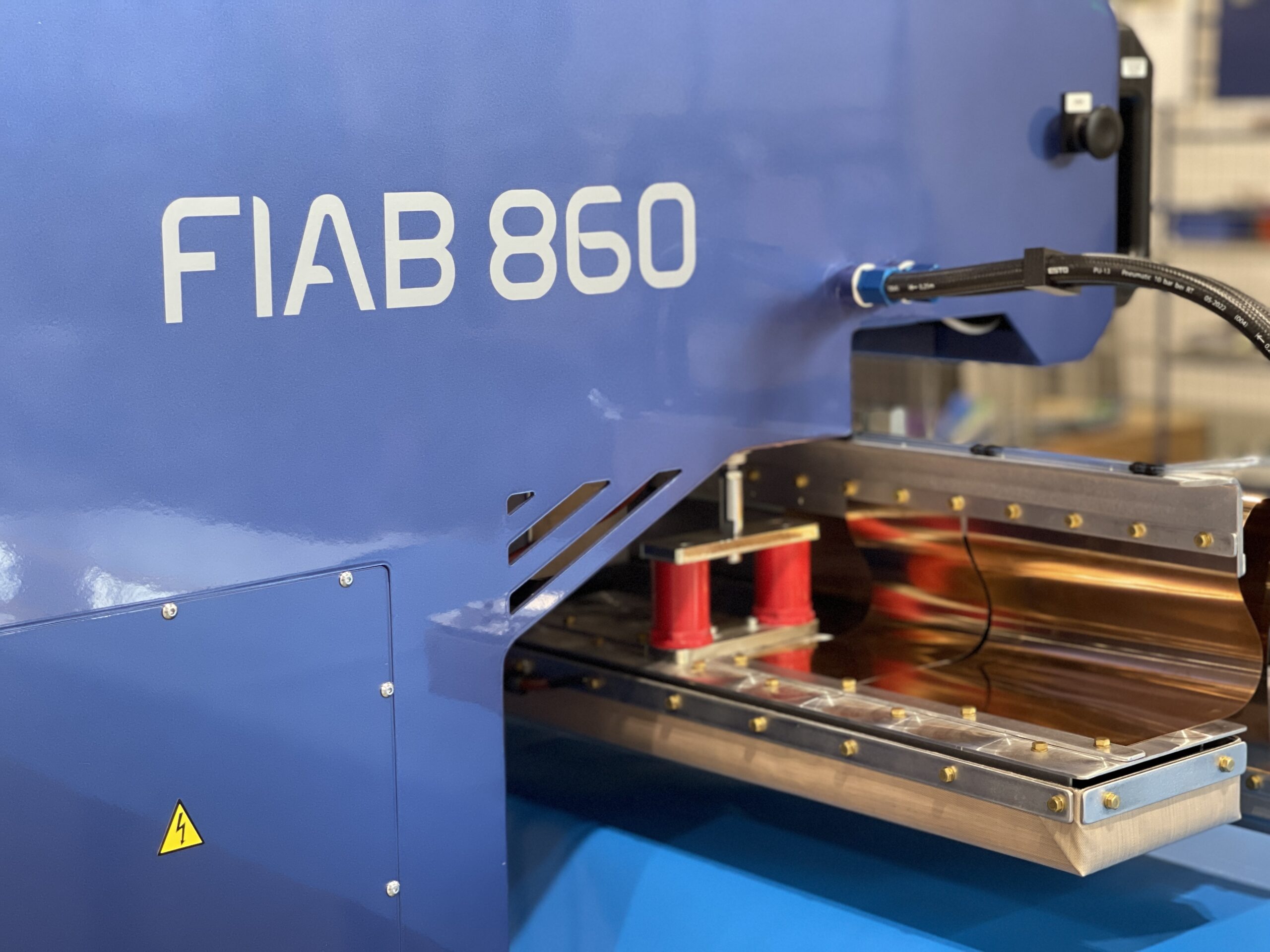

The Fiab 860 is ideal for materials with a weight of up to approximately 800g/cm². Useful for companies that are starting with the methodology of joining materials through HF (high frequency) and need flexibility and a quick return on investment. It’s ideal for companies that currently want to focus on the production of one or several medium-sized, uncomplicated products such as: truck tarps, terrace and gazebo roofing, or liquid-tight tanks, but have development prospects for additional projects.

Fiab 860 is the ideal welding machine for companies entering the HF market, as it was created to grow together with the company and the investor’s expectations regarding the welding machine’s capabilities.

Fiab 860 is designed to enable a quick return on investment.

Customers who most often choose the F860 are customers looking for a stationary machine, up to 8kW, or a mobile one with a short table. How to match the machine power to our needs is explained in the article under this link.

When purchasing the Fiab 860 welding machine in the stationary version, we can convert it at any time to a mobile version with a table up to 100m.

When is it worth choosing Fiab 860?

The difference lies in the generator power: Fiab 860 works with a power of up to 8 kW, while Fiab 960 reaches up to 22 kW. This affects the length of the tool that can be used, and consequently – the pace of production. Fiab 860 provides an excellent balance between investment and efficiency, enabling quick cost recovery and efficient order fulfillment.

And in the case of company development or moving to a larger hall, you can at any time transform Fiab 860 into a mobile version on a track system with a length of up to 100 m, while expanding the machine’s functionality with additional options related to mobile versions, such as positioning lasers, magnetic strips for material positioning, or automatic welding.

Fiab 960 is a welding machine created with medium and large companies in mind that need greater power for big challenges for faster production.

It’s the ideal solution for manufacturers welding long blocks of materials in a straight line, such as biogas membranes, tent halls, or the production of membrane architecture like stadium, stage, and platform roofing.

As our flagship model, produced almost serially, Fiab 960 offers a generator with a power from 13 kW to 22 kW and the ability to work with an electrode with a length of up to 2000 mm, which allows for quick and precise joining of large material surfaces. The machine works excellently when there’s a need for long tables and with materials with a weight above 800 g/m². It’s virtually indispensable in the production of all kinds of waterproof products, especially environmental ones. Unmatched, among others, in the production of firefighting tanks, flood barriers, digestate and slurry tanks.

This type of product requires the use of completely impermeable materials and the highest quality, durable, and waterproof welds that guarantee complete tightness of the structure, protect the environment from substance leakage, and ensure long, trouble-free operation.

Fiab 960 can be equipped with a number of additional options, including: double positioning lasers, a pressing press with dimensions of up to 2000 × 300 mm, enabling the use of electrodes of any shape and welding even the most complex patterns, as well as SBS systems supporting work with materials difficult to weld, flame-retardant, and non-flammable.

Thanks to these solutions, Fiab 960 is the ideal choice for the production of specialized military accessories, such as pneumatic military tents or flexible tanks for drinking and industrial water. It also works well in the production of pontoons or PVC covers.

When is it worth choosing Fiab 960?

Increased generator power allows for better material penetration, which translates into a uniform, durable, and waterproof weld even with large layer thickness.

Fiab 960 also works excellently with tools equipped with elements with insulating properties (e.g., Teflon), which require higher HF energy to achieve the proper welding effect.

Thanks to precise power and time control the device maintains stable process parameters, which guarantees repeatability and high production quality.

An additional advantage is the ability to increase the working cycle speed while maintaining full control over temperature and weld uniformity, which significantly increases the efficiency of the entire production line through the use of the automatic welding function.

Higher generator power not only speeds up the welding process itself but also enables the use of electrodes with a length of up to 2000 mm, which allows joining a larger material surface in one cycle and shortens the total production time by up to several hours per week.

Among the advanced but less extreme needs, we can also include membrane architecture – the production of sun sails, exhibition pavilions, or roofing for stadiums and platforms also requires precise and strong connections of elements with varied weights, properties, and shapes. FIAB 960 enables the execution of such connections while maintaining the highest quality and repeatability standards thanks to, among other things, the possibility of ordering special electrodes, tools, and complementary machines like KEDER SYSTEM.

Unlike buying a car, in the case of FIAB 960, nothing is “forever.” We can convert your stationary welding machine to a mobile version at any time, thus adding automation functions. The track system can be easily extended by additional meters, and at your request, at any time we can also equip the machine with additional steps such as additional lighting, pressing press, operator platforms, double positioning lasers, and many other options.

The only element that needs to be determined at the ordering stage and that remains unchanged is the welding machine power. Everything else you can adapt, modernize, and develop in the future – exactly as the needs of your production change.

Summary

The choice between Fiab 860 and Fiab 960 is not a simple comparison of power or price – it’s a strategic decision, dependent on the scale of your production, type of materials, available space, and company development plans.

Fiab 860 is an excellent choice for those who are just entering the world of high-frequency welding or implementing medium-scale production. It ensures a quick return on investment, compact construction, mobility, and the possibility of expansion in the future. It’s a machine that allows starting production without great financial risk while providing space for development.

Fiab 960, on the other hand, is a solution for enterprises that need power, speed, and reliability in larger-scale production. It works excellently in demanding projects – from membrane architecture to military and industrial applications, where durability, repeatability, and the highest weld quality count.

Both models are united by one thing – the philosophy of development together with the user’s company. Both Fiab 860 and Fiab 960 can be expanded, equipped, and adapted to new production challenges. Thanks to this, every investment in a FIAB welding machine is a long-term decision, supporting your development today and in the future.

If you’re still wondering which model will be best for you – contact us. Our advisors will help you select the ideal machine configuration for your needs, so that HF welding becomes not only effective but also profitable.

FIAB Sp. z o.o. Bronisław Koziołkiewicz Sp. k.

Wrocław 54-615

ul. Rakietowa 38

POLAND

NIP 8942999829

KRS 0000357875

REGON 021278590

BDO 000072061

By sending the inquiry to sales@fiabmachines.com, info@fiabmachines.com you agree to process your personal data for marketing purpose. If you do not agree on that, please inform us via e-mail.

Copyright © 2025 FIAB Machines