How to choose your first HF welder? 5 key criteria

23-9-2025

Picking your first high-frequency (HF) welder is a big step for any business getting into plastic welding. The right choice can boost your production efficiency and open up opportunities for growth. In this article, we’ll walk you through 5 key factors to consider, making it easier to choose the welder that’s perfect for your needs.

1. Analyzing Production Needs – The Foundation of a Smart Choice

Before browsing specific models, take a close look at your production needs. Consider:

Type of products you want to make:

- Are you planning to produce tarpaulins, tents, inflatable boats, or waterbeds?

- Are you focusing on awnings, banners, or protective clothing?

- Or do you see your future in the medical or automotive industry?

Production scale:

- How many products do you plan to make daily or weekly?

- What is the size of the items to be welded?

- Do you need a machine for continuous operation or occasional use?

These questions are crucial because different welder models are optimized for different applications. For example, the FIAB 500 was designed in collaboration with customers to support production lines within a specific range, while the FIAB 860 offers greater versatility and growth potential.

2. Comparing Entry-Level Models: FIAB 500 vs FIAB 860

FIAB 500 – Budget-Friendly Option for Beginners

The FIAB 500 is a stationary welder designed for companies just starting with HF technology. Its main advantages are:

- Ease of use – perfect for beginner operators, with physical buttons instead of complex screens or programs.

- Specialization – ideal for reinforcing seams, producing tarpaulins, curtains, water and food containers for animals, and car covers.

- Stability – stationary construction ensures precise, repeatable welding.

- Affordable – the lowest entry point into HF technology.

Applications for FIAB 500:

- Protective clothing and awnings

- Signs and banners

- Inflatable boats and water equipment

- Sun and rain protection products

- Small waterproof items

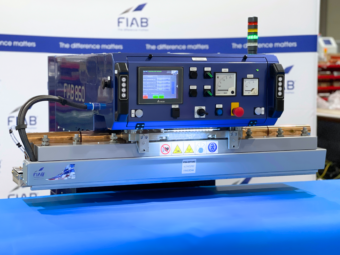

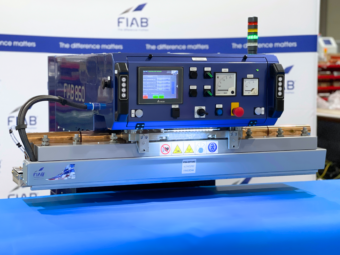

FIAB 860 – Versatility and Growth Potential

The FIAB 860 is the natural successor to the FIAB 500, designed for greater versatility and production comfort:

- Two power options – 5 kW and 8 kW for different needs

- Flexible configuration – available in stationary and mobile versions

- Upgradeable – easily converted from stationary to mobile

- Wider application range – from small components to larger structures

Unique Features of FIAB 860:

- Tool holder up to 1250 mm; heating surface up to 320 cm²

- Optional wide pressing plate for various electrode shapes

- Recipe memory (save welding parameters for different materials or electrodes)

- Worktable expandable up to 100 meters

- Accessories for mobile version: easier material positioning with laser pointers or magnetic strips, extra lighting, anti-slip floor; for stationary version: foot pedal control

3. Budget vs. Functionality – Finding the Sweet Spot

Choosing your first HF welder often involves a trade-off: go for a cheaper option or invest in a more advanced model?

When to choose FIAB 500:

- Current methods like sewing or hot air are no longer sufficient, and you need durable, waterproof connections.

- Limited startup budget

- Clear production profile (tarpaulins, PVC awnings, protective curtains)

- Small production volumes

- No plans for rapid expansion

- Simple production with fixed electrode sizes

When to invest in FIAB 860:

- You need flexibility for irregular shapes and frequent electrode changes

- Producing multiple products requiring different tools

- Works with materials up to ~800 g/m² and medium-sized products (car tarpaulins, water and oil tanks, industrial covers, banners, small seasonal tents)

- Ideal for both small fragments (up to 8 meters) and larger surfaces (up to 25 meters)

- Planning company growth

- Need for flexible production setups

FIAB 860 can grow with your business – start stationary and later expand to a mobile version with a 100-meter worktable. Perfect as an entry-level investment that scales.

4. Workshop Space – Match the Machine to Your Facility

Analyzing available workshop space is often overlooked but crucial.

Space requirements:

FIAB 500:

- Compact stationary design

- Four stable and leveled support points

- Ideal for smaller workshops

- Transport wheels allow repositioning without a dedicated spot

FIAB 860:

- Stationary version with transport wheels – easy to move

- Flexible configuration – quick tool changes and additional options

- Upgradeable to mobile version with up to 100 meters of worktable

Planning the space:

- Ensure safety zones around the machine

- Allocate material storage

- Consider access to power (electrical installations, grounding, etc.)

- Plan material flow in the production process

5. Planned Company Growth – Investing in the Future

HF welders are a long-term investment, so think strategically.

Future considerations:

- Where do you see your company in 3–6 years?

- Are you planning to expand your product range?

- Will production volumes increase?

- Might you need a mobile machine in the future?

If yes – choose FIAB 860; if no – choose FIAB 500.

Growth paths:

With FIAB 500:

- Great start for companies with a single product

- Easy to add machines as you grow

- Specialization in specific products

With FIAB 860:

- One machine, many products, multiple growth opportunities

- Upgradeable from stationary to mobile

- Expandable worktable up to 100 meters

- Flexible production profile

Your Decision

Choosing your first HF welder will impact your company for years. Both FIAB 500 and FIAB 860 have unique advantages tailored to different business strategies.

Choose FIAB 500 if:

- You want a stationary machine

- You have a clear product profile

- You need a simple, reliable machine with precise, waterproof HF connections

- You plan gradual growth with additional machines

Choose FIAB 860 if:

- You’re thinking long-term and may need a mobile version later

- You want product flexibility

- You plan to scale production

- You value upgrade and expansion options

No matter your choice, you benefit from FIAB’s 71 years of experience, delivering machines to 64 countries worldwide – a guarantee of quality, reliability, and top-notch technical support.

Remember: The best welder is the one that meets your real needs and capabilities. Don’t hesitate to consult FIAB experts – their experience will help you make the best decision for your business.