FIAB SHUTTLE TABLE is a machine equipped with single or double-sided shuttle table. Possibility of applying of cutting - and - welding tools in various shapes. This highly customized machine is dedicated especially to automotive and medical industry. The welding is designed as a two – stage process. Table sections are managed independently.

The operator prepares the product on the table and places the tools on top of it (the tool can be also fixed with the press). Then he presses the start button and the machine starts welding the product in two steps automatically according to the pre-set recipe. The recipe can be stored on the computer, on a flash card or USB memory stick. You can save unlimited number of recipes.

Standard design:

- round return from four sides is for safety and functional production,

- four pillar press with cylinders for exact and equal press pressure over all area,

- self-centering system with locking screws.

If you are going to produce cleats for conveyor belts – we can offer you a special model FIAB FT, which has a similar construction to FIAB Shuttle Table regarding the press, but it’s not equipped with sliding table.

The machine is strongly recommended for:

- Medical industry

- Automotive industry

- Military industry

- Packaging industry

- Large structures

- Conveyor belts

Machine especially recommended for the following industries:

Halls and tents

Tarpaulins

SIGNS & BANNERS

WATER & GAS TANKS

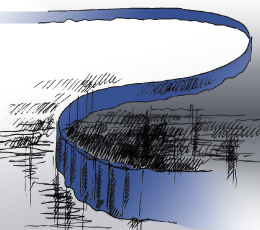

OIL BOOMS

Tensile Architecture & Membranes

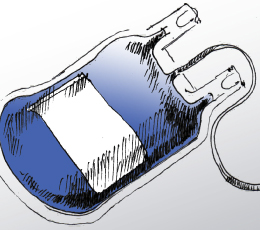

Medical

Large structures

Automotive

Contact

FIAB Sp. z o.o. Bronisław Koziołkiewicz Sp. k.

Wrocław 54-615

ul. Rakietowa 38

POLAND

NIP 8942999829

KRS 0000357875

REGON 021278590

BDO 000072061

By sending the inquiry to sales@fiabmachines.com, info@fiabmachines.com you agree to process your personal data for marketing purpose. If you do not agree on that, please inform us via e-mail.

Copyright © 2016 by LemOnHills Sp. z o.o.