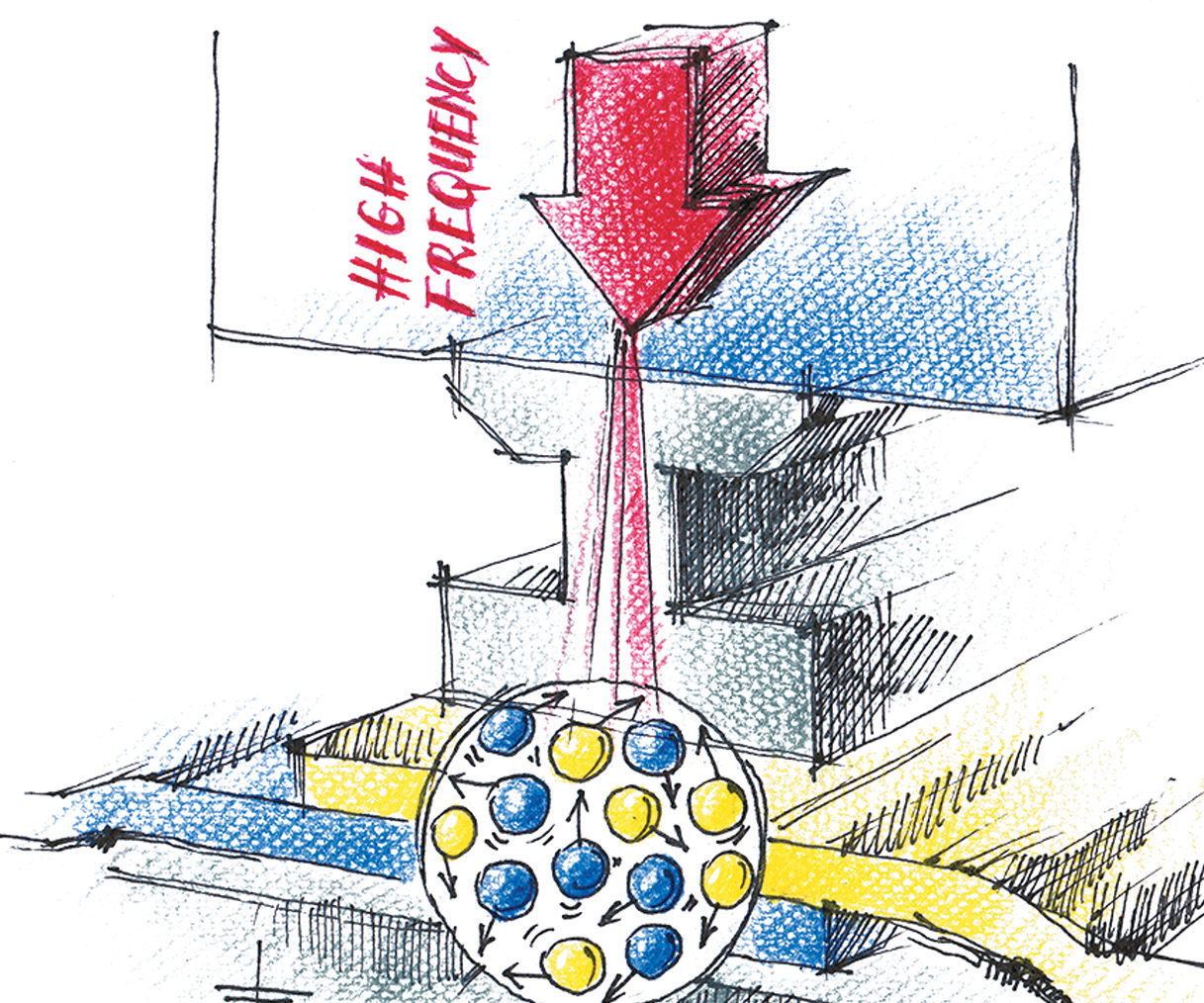

High frequency welding method uses a high frequency - usually 27,12 MHz – electromagnetic energy to excite the polar molecules of the dielectric materials placed between two welding electrodes, usually made of brass or aluminum. The electrodes are usually mounted in a pneumatic or hydraulic press to provide pressure for fusing the material, whereupon a high frequency voltage is connected to the plates. Every time the electric field changes, the dipole molecules of the polymer attempt to flip around to realign themselves to the new field orientation (orientation of dipoles is changing in the material twenty seven million times a second when follows reversing, HF electric field). As a result of the vibrating molecules is heating up to the melting (fusing) temperature. By bringing two layers of material into the HF field at the same time and pressing them together, the layers melt together (fuse) and form a strong welded joint.

The quality of a seal is determined by three key factors:

- temperature

- welding time

- pressure.

A proper adjustment of above parameters will result in the receiving a weld seam at least as strong or even stronger as the surrounding material.

Fast, one-step process

Stronger welds than with any other sealing technology

Water-proof, no light showing through

No wrinkles and puckers on the welded material

High quality welding process – the same every cycle

Possibility to automate the production

With SIEMENS touch panel in chosen language and unlimited storage of your welding 'recipes'

Due to the use of common spare parts, easily replaceable. This solution makes the service available and limits the downtime of the machine.

Quick electrode replacement through touch panel command

With advanced FIAB Security System - at design aspect. Declaration of conformity of the product to the essential requirements of the applicable CE marking directives – at workplace safety aspect.

Customized electrodes at affordable price

Due to energy-saving system and 'stand by' option

Contact

FIAB Sp. z o.o. Bronisław Koziołkiewicz Sp. k.

Wrocław 54-615

ul. Rakietowa 38

POLAND

NIP 8942999829

KRS 0000357875

REGON 021278590

BDO 000072061

By sending the inquiry to sales@fiabmachines.com, info@fiabmachines.com you agree to process your personal data for marketing purpose. If you do not agree on that, please inform us via e-mail.

Copyright © 2016 by LemOnHills Sp. z o.o.