The HPS Mini is an innovative, budget-friendly, mobile HF welding machine designed for welding reinforcements, finishes, details and for joining materials on large surfaces. It works well in places where you need to reach it without moving the material. Thanks to its compact design and high functionality, it performs excellently in industrial applications requiring precision and operational flexibility.

The device is characterized by power up to 8 kW and the possibility of using an electrode up to 400 mm long, which allows for making durable and uniform welds. The 180° rotating head enables welding at angles every 45 degrees, which significantly increases the range of applications and work precision.

Equipped with four travel wheels, which allows it to reach any place in the production hall. Ideal in conditions where maneuvering material takes far too much time.

In some cases, the device's low weight (only 520 kg) enables movement directly on the material, which eliminates the need for its time-consuming positioning.

A special, detachable frame allows height adjustment, thanks to which we can adapt it to work with a work table close to the ground, or slightly higher, which will enable comfortable work while standing.

The HPS Mini is an ideal solution in environments where the use of stationary welding machines or mobile ones on rail tracks is difficult or impossible. An excellent choice for companies looking for an efficient, versatile and mobile welding machine for large-format production applications, including industries such as: tarpaulin production, flexible tanks, roofing membranes, or pneumatic structures.

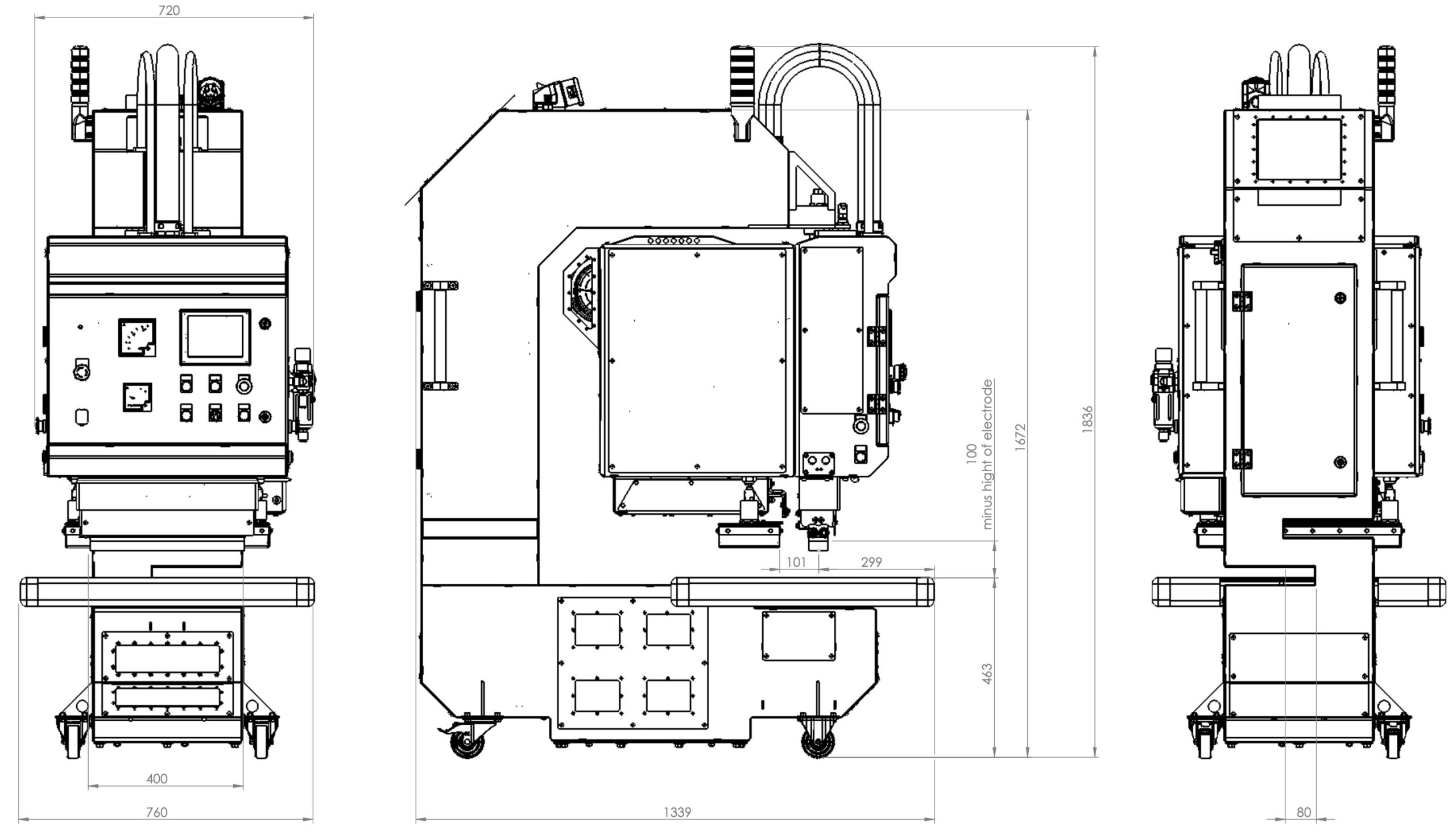

Thanks to its small dimensions, the FIAB HPS mini works excellently in places where space is limited. Its compact dimensions of 760 mm x 1339 mm width and 1836 mm height allow for easy maneuverability even in tight spaces. Additionally, thanks to being equipped with wheels, the machine can be easily moved in any direction on any hardened surface.

The FIAB HPS mini is a high-frequency welding machine - welded elements are not only durable, but also aesthetically pleasing. High-frequency technology allows for precise and fast welding, which significantly increases production efficiency. The most important feature of this welding machine is its compact dimensions and flexible and convenient operation, which is particularly useful when welding elements in hard-to-reach places.

The FIAB HPS mini is an ideal solution for various industries where mobility, precision and reliability are key factors. Regardless of whether you work in the automotive industry, tarpaulin production or in other sectors, this welding machine will provide you not only with excellent results, but also save time and resources.

What electrodes can you use in this machine?

- soft

- lamellar

- segmented, so-called "snake"

- tunnel

- double

- engraved, e.g. with logo

Ask our representative about additional accessories for your machine:

- laser indicators

- spare electrode magazine

- remote access facilitating servicing

- Industry 4.0

| Output power | 10 kW |

| Main fuse | D32 A |

| Voltage | 3x400V/50Hz+N+PE |

| Operating frequency | 27.12 MHz ± 0.6% |

| Cooling | oil/air |

| Electrode pressure (kg/cm2) | 700kG with 9 bar |

| Anti-flash | FIAB Security System |

| Compressed air pressure | min 6 bar, max 10 bar |

| Tool length | 400mm |

| Operating system | Beckhoff |

| Touch panel | Beckhoff |

| Machine weight | 520kg |

FIAB Sp. z o.o. Bronisław Koziołkiewicz Sp. k.

Wrocław 54-615

ul. Rakietowa 38

POLAND

NIP 8942999829

KRS 0000357875

REGON 021278590

BDO 000072061

By sending the inquiry to sales@fiabmachines.com, info@fiabmachines.com you agree to process your personal data for marketing purpose. If you do not agree on that, please inform us via e-mail.

Copyright © 2025 FIAB Machines