The FIAB 1900W is a machine from the Premium Monster segment, equipped with an electrode with an impressive length of up to 1800 mm, designed for maximum efficiency and working space. It was constructed to provide as much space as possible between the center of the electrode and its housing.

Thanks to this innovative design, 1900 mm of storage space was achieved behind the electrode, enabling convenient storage of large and heavy material rolls.

The machine weighs 4 tons and moves along the rail track at a speed of 1.5 m/s, making it one of the fastest in its class. It is equipped with laser sensors that serve as safety features, increasing operator work safety.

With durability and reliability in mind, the FIAB 1900W has been equipped with a central lubrication system for the rack rails, which significantly extends the lifespan of the entire mechanical system.

Additionally, the use of an automatic material unwinding system along the entire length of the table significantly improves daily work. The production process becomes faster, simpler and more efficient, resulting in clearly better operational results.

The combination of enormous dimensions, long electrode and high travel speed has created a monstrous machine that for a long time was the largest HF welding machine in the world. Its main task is to automatically weld the maximum number of meters of material in the shortest possible time, without compromising on precision.

Particularly recommended for the production of large structures such as tent halls, billboard advertisements, stadium roofing, airships.

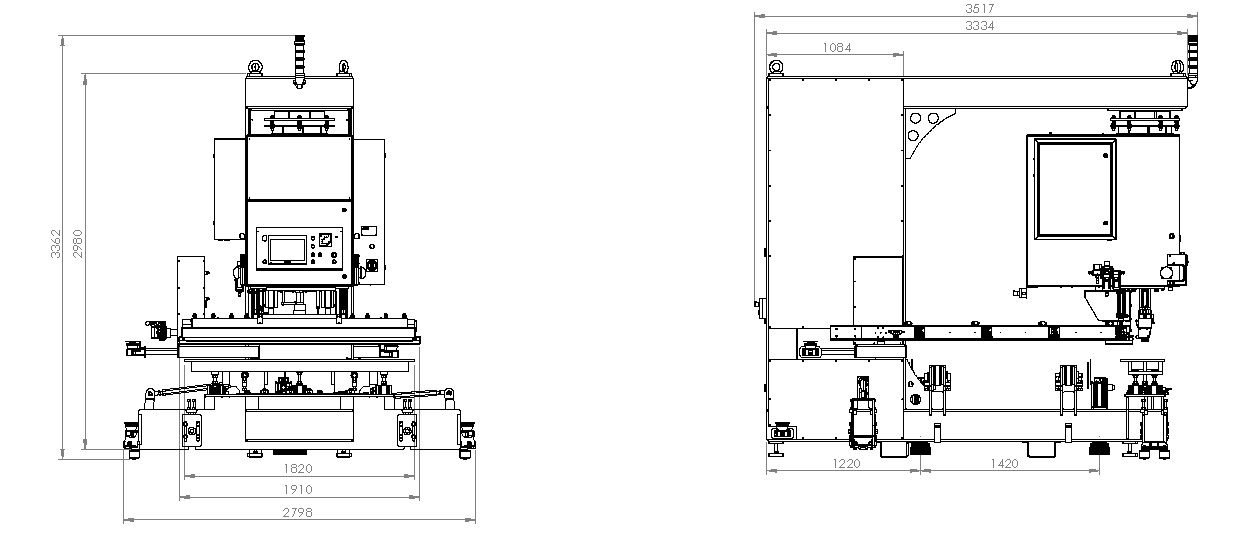

This is a welding machine of considerable dimensions (3362x3517x2798cm), which is why FIAB dedicates it to manufacturers who in their daily work join large-format material parts. The larger dimensions of the machine allow for comfortable work with, for example, large banners and billboards. The weight of this model without the rail track is approximately 4 tons.

The machine features a very long reach of up to 1.80m. Banner manufacturers will easily join large material elements together. Equipping the FIAB 1900W with an automatic material unwinding system along the entire length of the table streamlines daily production work; in this way, the entire process is significantly shortened and simplified, which directly translates into better and more efficient production performance.

The FIAB 1900W is equipped with obstacle detection scanners - if someone enters the scanner zone, the machine will stop immediately. Two servo drives are used as the drive system in the machine.

We have ensured longer machine lifespan by installing a central lubrication system for the rack rails.

| Voltage | 3x400V/50Hz |

| Operating frequency | 27.12MHz ± 0.6% |

| Cooling | oil |

| Pressure | 1200-2000kg |

| Anti-flash | Authorial FIAB |

| Air supply | min. 6bar |

| Compressed air consumption | 80L/cycle |

| Control system | OMRON |

| Touch panel | PROFACE |

| Machine weight | 4000kg |

| Remote diagnostics | for PLC and HMI |

| System of identification and storage of production regulations | Fiab Q |

| Tool Holder size | 1800mm |

| Speed of movement on the track | up to 1.5m/s |

FIAB Sp. z o.o. Bronisław Koziołkiewicz Sp. k.

Wrocław 54-615

ul. Rakietowa 38

POLAND

NIP 8942999829

KRS 0000357875

REGON 021278590

BDO 000072061

By sending the inquiry to sales@fiabmachines.com, info@fiabmachines.com you agree to process your personal data for marketing purpose. If you do not agree on that, please inform us via e-mail.

Copyright © 2025 FIAB Machines