HF Welding Technology in Large-Format Production

FIAB high-frequency welding machines are a solution created for manufacturers of large structures from thermoplastic materials. HF technology at a frequency of 27.12 MHz or 40.68 MHz ensures durable, hermetic welds on large surfaces, which are crucial in the production of tent halls, tanks, tarpaulins, and architectural membranes.

Applications in Large-Format Production

- Tent and storage halls – welding tarpaulin covers on steel structures

- Truck tarpaulins – production of covers for TIR trucks and trailers

- Flexible tanks – production of tanks for water, fuel, waste (up to 1000 m³)

- Architectural membranes – tensioned structures, pneumatic roofs, stretch ceilings

- Pontoons and boats – welding pneumatic structures

- Flood barriers – production of protective barriers

- Pools and pool liners – pool liners and covers

- Awnings and canopies – large-format shading systems

FIAB Models for Large Structures

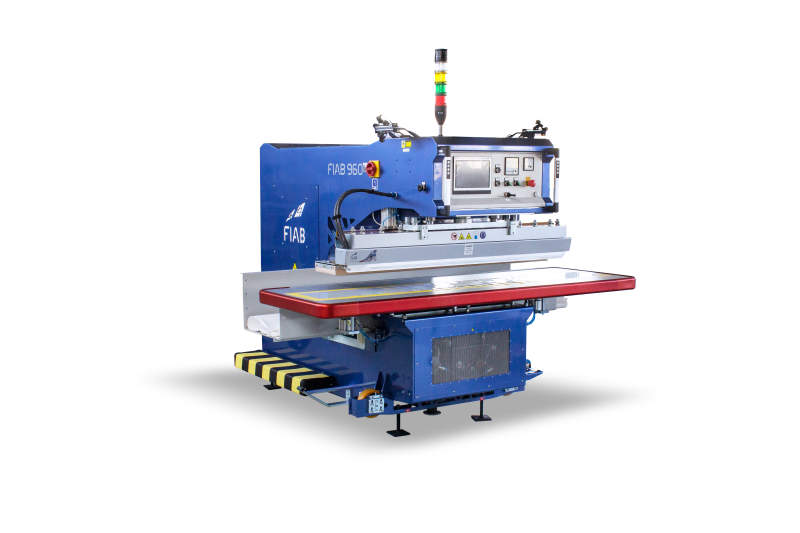

FIAB 500, 860, 960 – mid-range machines with 5-8 kW power and electrode length up to 700-800 mm, ideal for medium production of tarpaulins and tent halls.

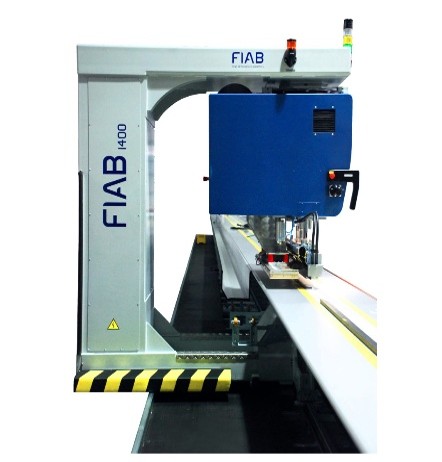

FIAB 1400 – premium series (13-26 kW) with electrode up to 1500 mm and welding area up to 750 cm². Available in mobile and stationary versions. Construction enabling welding "from the inside" facilitates handling of large-format materials.

FIAB 1400LS – quiet version for production halls with acoustic requirements.

FIAB 1900W and 2060W – machines with the largest working width for extremely wide structures.

FIAB HPS-MINI – mobile wheeled welding machine (8 kW, 400 mm electrode) with 180° rotating head. Ideal for on-site welding without material transport.

FIAB XYZ-SPIDER – movable head in 3 axes for welding spatial contours.

Advantages of HF Technology in Large-Format Production

- Weld strength – joints stronger than the base material

- Tightness and waterproofing – hermetic welds for tanks and structures

- Process speed – cycles counted in seconds

- Precision – parameter repeatability in serial production

- Adhesive-free technology – elimination of solvents and adhesives

- Aesthetics – smooth, even welds without visible joining marks

Materials for Large Structures

- Coated PVC (650-900 g/m²) – truck tarpaulins, halls

- Architectural PVC – structural membranes

- Polyurethane – flexible tanks, pontoons

- Layered composites – fiber-reinforced materials

Specialist Electrodes

- Lamellar electrodes – linear welds

- Tunnel electrodes – application of piping and reinforcements

- Curved electrodes – welding windows and openings

- Engraved electrodes – embossing logos

Production Process

- Material cutting according to design

- Positioning on welding table

- Welding sections with parameter control

- Assembly of reinforcements, eyelets, piping

- Quality and tightness control

- Packaging and transport

Infrastructure and Requirements

- 3x400V power supply (25-63A)

- Compressed air 6-7 bar

- Production hall min. 25-100m length (for mobile versions)

- Ventilation system

Integration with Industry 4.0

FIAB 1400 series machines offer:

- SIEMENS SIMATIC panel with touchscreen

- Integration with MES/SCADA systems

- Remote monitoring and diagnostics

- Quality documentation compliant with industrial standards

Production Efficiency

HF technology allows for:

- Production of hundreds of square meters daily

- Cycle time reduction of 60-80% vs traditional methods

- Minimization of production defects

- Reduction of operating costs

Application Examples

- Tent hall covers with area of 500-5000 m²

- Tarpaulins for 13.6m trailers

- Flexible tanks up to 1000 m³

- Roof membranes with span of 50m+

- Rescue and military pontoons

- Portable and permanent pools

FIAB welding machines are professional tools for manufacturers of large structures, combining high efficiency, precision, and weld durability. The machine portfolio includes solutions from medium production to high-volume industrial plants.