HF Technology in the Production of Oil Spill Containment Booms

FIAB high-frequency welding machines are a professional solution for manufacturers of oil booms and spill containment barriers. HF technology ensures hermetic, durable welds resistant to extreme aquatic environments and chemicals.

Applications in Environmental Protection

- Oil sorbent booms – hydrophobic barriers absorbing oil and petroleum products

- Offshore containment booms – pneumatic barriers for open waters

- Harbor booms – barriers for ports, marinas, docks

- River booms – barriers for flowing waters and canals

- Rigid and flexible booms – curtain and pneumatic structures

- Oil skimmers – overflow-pump and adhesive systems

- Curtain booms – curtain barriers for containing spills

- Quick response booms – lightweight rescue booms for vessels

Types of Oil Booms

Sorbent Booms

Filled with hydrophobic (water-repelling) fiber, they float on the surface even after absorbing oil. They absorb crude oil, gasoline, engine oils, and other petroleum products.

Pneumatic Barriers

Air-filled, lightweight for transport, high buoyancy on waves. Used on open waters and for rapid emergency response.

Curtain Booms

Impermeable structures made of reinforced PVC/PU fabric, secured with steel cables. For long-term protection of water bodies.

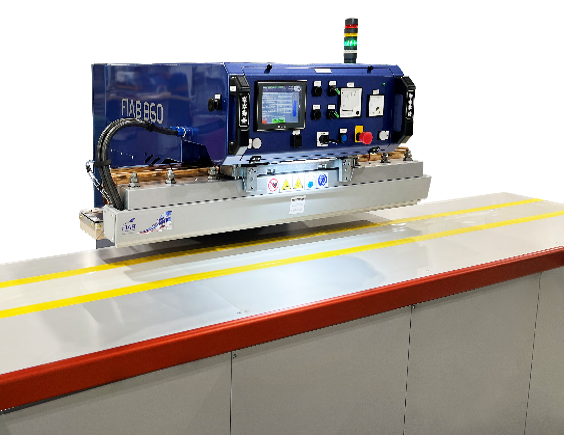

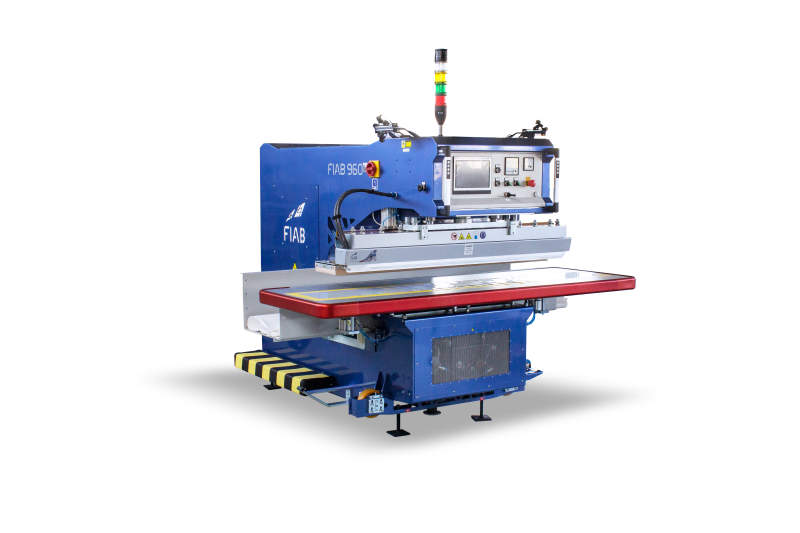

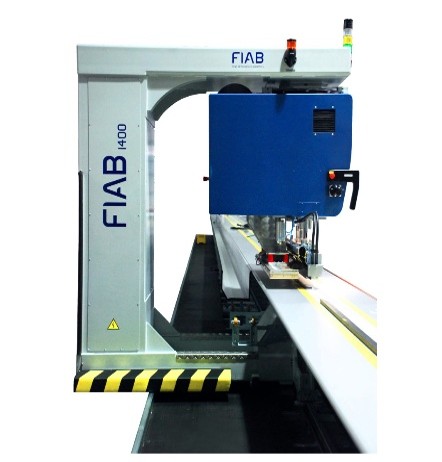

FIAB Models for Boom Manufacturers

FIAB 360, 500 (3-5 kW) – machines for producing small sorbent booms (Ø 13-20 cm x 3-6m).

FIAB 960 (8 kW) – welding machine for medium barriers up to 10-20m in length.

FIAB 1400 (13-26 kW) – industrial series with electrode up to 1500 mm for producing large-format offshore booms. Mobile construction enables welding of barriers 50-100m in length.

FIAB 1900W, 2060W – largest machines for extremely wide marine booms.

Materials for Oil Booms

- Coated PVC (650-1200 g/m²) – fabrics resistant to oils and chemicals

- Polyurethane (PU) – elastic hydrophobic materials

- Neoprene – fabrics resistant to UV and petroleum products

- Polypropylene nonwovens – sorbent materials for fillings

Properties of Oil Booms

- Resistance to crude oil, gasoline, oils, BTEX, PAH

- Hydrophobicity – water repellency, floating on surface

- UV resistance and weather conditions

- Tensile strength 2000-5000 N/5cm

- Sorption capacity up to 200 liters of oil per boom

- Durability 5-10 years of operation

Construction of Oil Booms

- Outer shell – PVC/PU fabric welded with HF

- Filling – sorbent nonwoven or pneumatic chambers

- Reinforcements – internal steel cables bearing loads

- Nylon mesh – protective outer coating

- Metal connectors – systems for connecting booms into chains of any length

- Mooring ropes – handles for anchoring and towing

Oil Boom Production Process

- Cutting PVC/PU fabric according to dimensions

- HF welding of shell into tube/sleeve form

- Inserting sorbent nonwoven or mounting pneumatic valves

- Welding ends and applying connectors

- Mounting steel cables and handles

- Tightness and buoyancy control

- Flotation and sorption capacity testing

Advantages of HF Technology

- Tightness – hermetic welds preventing oil leakage

- Strength – welds resistant to stress during towing

- Chemical resistance – welds undamaged by oil and chemicals

- Durability – connections resistant to UV, waves, extreme temperatures

- Speed – production of hundreds of meters of booms daily

- Precision – parameter repeatability in serial production

Standards and Certificates

- PZH certificate (National Institute of Hygiene)

- Fire resistance certificates

- NATO standards for military applications

- ISO 14001 – environmental management

- Certification for marine rescue services

Special Applications

- Port and marina protection – permanent barriers at quays

- Water fuel stations – booms around refueling piers

- Offshore operations – protection of drilling platforms

- Maritime transport – emergency barriers on vessels

- Maintenance work – securing bridges, quays

- Water body cleanup – booms for concentrating pollution

- Military protection – mobile field barriers

Production Efficiency

- Production of 200-1000m of booms daily (depending on type)

- Cost reduction of 50% vs traditional methods

- Minimization of defects to 2%

- Long boom lifespan (5-10 years)

Infrastructure

- Production hall min. 20-50m in length

- 3x400V power supply (25-63A)

- Welding tables or rail tracks

- Ventilation for PVC fumes

FIAB welding machines are a reliable solution for oil boom manufacturers, ensuring hermetic seal, strength, and compliance with aquatic environmental protection standards.