HF Technology in the Production of Transport Tarpaulins

FIAB high-frequency welding machines are a professional solution for manufacturers of tarpaulins for heavy-duty vehicles. HF technology ensures durable, sealed welds with strength exceeding the base material – crucial for transport safety and cargo protection.

Applications in the Transport Industry

- TIR trailer tarpaulins – curtains, curtain-siders, standard and MEGA/JUMBO canopies (13.6m)

- Curtain tarpaulins – sliding systems with customs closures

- Side tarpaulins – with reinforced edges and fastening tunnels

- Sliding roofs – folding structures for top loading

- Anti-burglary tarpaulins – reinforced with steel mesh

- Tarpaulins for vans and delivery vehicles – covers for 3.5-7.5t vehicles

- Agricultural trailer tarpaulins – tippers, platforms, containers

- Tarpaulins with advertising prints – full color branding for fleets

FIAB Models for Tarpaulin Manufacturers

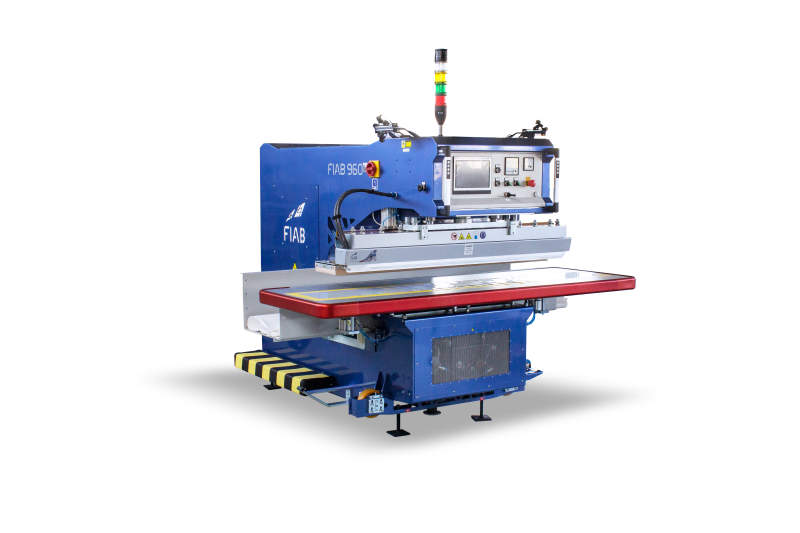

FIAB 500, 860, 960 – machines with 5-8 kW power and electrode up to 700-800 mm for producing tarpaulins for vans, trailers, and smaller semi-trailers.

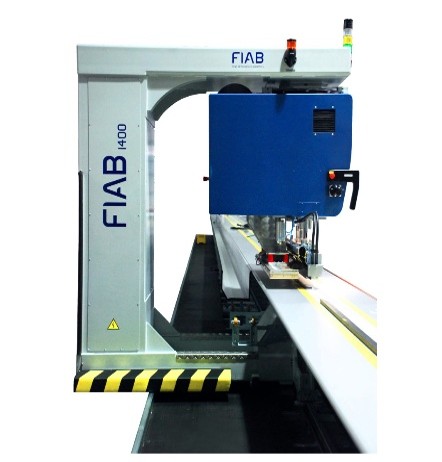

FIAB 1400 (13-26 kW) – industrial series with electrode up to 1500 mm and welding area 750 cm². Construction enables welding of tarpaulins 13.6m long without interrupting the material. Available in stationary and mobile versions.

FIAB 1900W and 2060W – maximum weld width for producing wide MEGA tarpaulins (3m height).

FIAB HPS-MINI – mobile 8 kW welding machine on wheels with 180° rotating head, ideal for repairs and on-site production.

Advantages of HF Technology

- Mechanical strength – welds stronger than the material

- Waterproofness – hermetic connections securing cargo

- Speed – welding cycles in seconds

- Precision – industrial repeatability compliant with EN 12641 and EN 13642 standards

- Aesthetics – smooth welds for advertising prints

- Durability – tensile resistance up to 3500 N/5cm

Materials for Transport Tarpaulins

- Coated PVC (650-900 g/m²) – polyester fabrics coated with PVC

- Certified materials – compliant with EN and CMR standards

- Flame-retardant fabrics – for transport of hazardous materials

- Blockout – opaque for light-sensitive goods

Tarpaulin Elements Welded with HF

- Main welds – connections of side and roof panels

- Fastening tunnels – pockets for tension ropes and piping

- Corner reinforcements – attachment points to trailer structure

- Anti-theft strips – insertion of steel cables

- Transparent windows – mounting of clear PVC inserts

- Customs closure pockets – application of security systems

- Prints and logos – welding additional layers with graphics

TIR Tarpaulin Production Process

- Cutting panels according to trailer dimensions (13.6m x 2.7-3m)

- Large-format advertising printing on panels

- Welding panels into complete tarpaulin

- Application of tunnels, reinforcements, and eyelets

- Mounting fastening and closure systems

- Strength and tightness control

- Packaging and delivery

Standards and Certifications

- EN 12641-2 (XL) – strength of curtain tarpaulins

- EN 13642 – XL code for high-strength trailers

- CMR – Convention on international road transport

- TIR – approval for international transport

Production Efficiency

HF welding machines enable:

- Production of 5-15 complete TIR tarpaulins daily (depending on configuration)

- Reduction of welding time by 70% vs traditional methods

- Minimal material waste (below 3%)

- Tarpaulin longevity 5-8 years of operation

Tarpaulin Service and Repair

FIAB HPS-MINI welding machines are ideal for service workshops offering:

- Repair of mechanical damage (tears, cuts)

- Replacement of side and roof sections

- Regeneration of customs closures

- Replacement of eyelets and fastening tunnels

- Welding repair patches

Production Infrastructure

- 3x400V power supply (25-63A)

- Production hall min. 20m length

- Welding tables or rail tracks for mobile versions

- Compressed air 6-7 bar (for pneumatic models)

FIAB welding machines are a proven solution for transport tarpaulin manufacturers, combining efficiency, weld quality compliant with international standards, and reliability in daily industrial operation.