What are High-Frequency Welding Machines in Hall Production

High-frequency welding machines are key equipment in the production of tent hall covers. HF technology (27.12 MHz) creates welds with strength exceeding traditional thermal welding methods. Unlike hot air welding, where material is joined superficially, HF technology integrates the molecular structures of the material, creating a connection indistinguishable from the base material.

Applications in Tent Hall Production

FIAB welding machines are used to produce all key hall elements:

- Roof covers – welding strips of PVC material 650-900 g/m² for hall roofs with area of 500-5000 m²

- Side walls – production of tarpaulin panels with windows and doors

- Curtains/gates – welding sliding hall closure elements

- Piping and tunnels – application of fastening systems to steel structure

- Reinforcements – welding reinforcing strips under clamps and frames

- Transparent windows – integration of transparent film with tarpaulin material

- Connecting elements – production of corners and structural connections

FIAB Welding Machine Portfolio

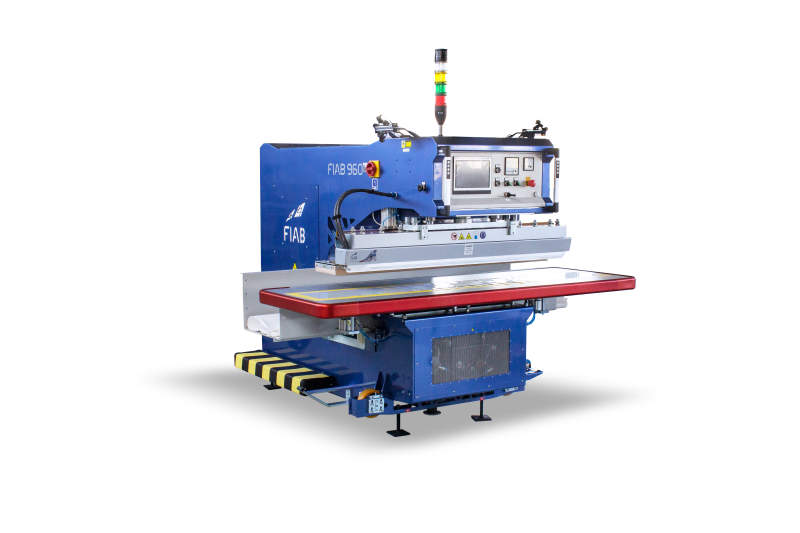

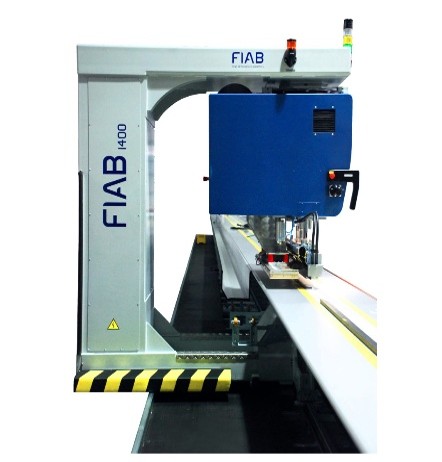

For small and medium tarpaulin production, FIAB 500, 860, 960 machines with 5-8 kW power and electrode length of 700-800 mm are used. For industrial production, FIAB 1400 (13-26 kW, electrode up to 1500 mm) is dedicated, available in stationary and mobile versions. Mobile FIAB HPS-MINI enables repairs and welding directly on the structure.

Why HF Welds are Better

PVC material welded with HF method is characterized by:

- Tensile strength – welds stronger than the material itself

- Weather resistance – resistance to UV, frost (-40°C), rain, wind

- Tightness – no micro-leaks, complete waterproofing

- Durability – lifespan of 15-25 years in year-round operating conditions

- Safety – no adhesives and solvents

Hall Cover Production Process

- Cutting – cutting PVC material according to design

- Strip welding – joining sheets with overlap (30-50 mm)

- Reinforcement application – welding strips under clamps and fastenings

- Piping welding – mounting fastening systems to profiles

- Window mounting – integration of transparent film

- Finishing – mounting eyelets, clamps, locks

- Control – tightness and strength testing

Materials Used in Halls

- Coated PVC (650-900 g/m²) – standard for year-round halls

- Architectural materials (1100-1300 g/m²) – large roof spans

- Transparent films – windows and skylights in halls

- Flame-retardant fabrics – sports and event halls

Types of Welds in Hall Production

- Overlap weld – basic strip joining (30-50 mm width)

- Tunnel weld – pockets for beams and structures

- Reinforcement weld – application of strips under clamps and frames

- Piping weld – mounting fastening systems

- Window weld – integration of transparent elements

Electrodes for Tent Hall Production

- Lamellar electrodes (700-1500 mm) – linear welds

- Tunnel electrodes – pockets and tubes

- Double electrodes – simultaneous welding of two lines

- Curved electrodes – arches and contours

Efficiency and Economics

HF welding machine compared to traditional methods:

- Speed – 10-15 m/min linear weld

- Efficiency – 200-500 m² of cover daily (1 operator)

- Time savings – reduction of 60-70% vs manual welding

- Quality – 100% parameter repeatability

- Durability – minimal machine maintenance

Technical Requirements

- Power supply: 3x400V/50Hz (protection 25-63A)

- Compressed air: 6-7 bar, 50-220 l/min

- Area: hall min. 25-100m length (mobile versions)

- Work table: 800-2000 mm width

Production Integration

FIAB 1400 machines equipped with:

- SIEMENS panel with parameter programming

- Recipe memory for different materials

- Monitoring of weld time and quality

- Production documentation

Service and Support

FIAB provides:

- Operator training in PVC welding

- Technical consulting on parameter selection

- Warranty and post-warranty service

- Spare parts availability

- Support in process optimization

Certificates and Standards

FIAB machines meet:

- CE standards for machine safety

- EMC requirements for electromagnetic compatibility

- ISO 9001 quality standards

High-frequency welding machines FIAB are the standard in modern tent hall production. HF technology ensures the strength, tightness, and durability of welds necessary for structures operated in harsh weather conditions for many years. The FIAB machine portfolio offers solutions from small workshops to high-volume production facilities.