High-frequency welding machines form the foundation of modern advertising material production. HF technology uses a generator producing energy at a frequency of 27.12 MHz or 40.68 MHz, which acts on the material in the form of an electromagnetic field. Molecules in the fabric structure are set in motion, generating heat that melts the material and creates exceptionally durable, hermetic connections.

In the production of advertising banners, HF technology guarantees connections with significantly higher strength than traditional sewing or gluing methods. Welds made using this method are characterized by resistance to stretching, weather conditions, and intensive use, which is crucial for outdoor advertisements exposed to wind, rain, and UV radiation.

FIAB high-frequency machines find wide application in the advertising industry, enabling the production of various elements:

HF welding machines allow for precise finishing of banner edges for eyelet mounting, welding pockets for poles and rods, mounting reinforcements, and applying anti-theft tapes. The technology ensures aesthetic finishing and absolute weld strength against adverse external factors.

FIAB 360 is a compact stationary welding machine with 3 kW power, ideal for advertising agencies and small large-format printing shops. With a maximum electrode length of 200 mm and welding area of 54 cm², it performs excellently in the production of small banners, advertising signs, and light box elements. The machine is equipped with the FIAB Security System protecting against arc damage.

FIAB 500 offers 5 kW power and a welding area of 140 cm² with electrode length up to 700 mm. This is a universal solution for medium production of banners, advertising signs, and advertising pontoons. This welding machine was designed in cooperation with customers, guaranteeing optimal support for production lines in the advertising industry.

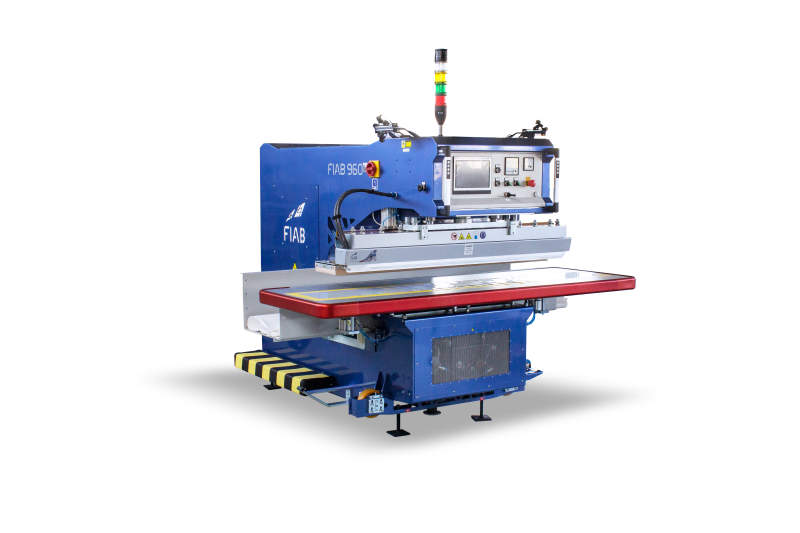

FIAB 960 is the flagship mid-range model with a wide range of electrode options – from lamellar, through curved for welding windows in banners, to engraved with company logos. The machine offers excellent efficiency in the production of tent halls, canopies, stretch ceilings, and large advertising banners.

FIAB 1400 is a premium welding machine available in four power variants (13, 17, 22, 26 kW), designed for production facilities working with large-format advertising materials. The unique construction enables the operator to position directly behind the electrode, which significantly facilitates control of the welding process for large banners and advertising structures.

The machine is equipped with a SIEMENS SIMATIC operating system with a touch panel, oil cooling, and a welding area up to 750 cm² with electrode length reaching 1500 mm. The electrode pressure is 1920 kg/cm², which guarantees excellent weld quality even in the case of difficult, multi-layer materials.

FIAB 1400LS is a variant with reduced noise level, particularly valued in production halls where operator work comfort matters.

FIAB 360L and FIAB 1400LS are versions with reduced noise emission, ideal for environments requiring quiet operation.

FIAB 1900W and FIAB 2060W are solutions with very large working width, intended for the production of extremely wide banners, tent halls, and architectural structures.

FIAB HPS-MINI and FIAB HPS-Q-DRIVE are machines with a hydraulic system, offering the highest precision of pressure when welding delicate advertising materials.

FIAB XYZ-SPIDER is an innovative welding machine with a head movable in three axes, enabling welding of complex shapes and contours without the need to move the material.

The application of high-frequency technology in the production of advertising materials brings a number of benefits:

FIAB high-frequency welding machines work with a wide range of materials used in the advertising industry:

Professional production of advertising banners using HF technology includes several key stages:

FIAB machines offer a rich selection of electrodes adapted to specific applications in the advertising industry:

HF welding machines significantly increase the efficiency of advertising material production. Compared to traditional hot air welding or sewing methods, high-frequency technology allows achieving:

FIAB high-frequency welding machines require appropriate infrastructure preparation:

FIAB machines are designed with easy operation and minimal maintenance requirements in mind:

FIAB high-frequency welding machines represent a professional solution for companies engaged in the production of banners, signs, and other advertising materials. They offer a combination of high-quality workmanship, end product durability, production efficiency, and application flexibility. From small advertising agencies to large production facilities, everyone will find in the FIAB portfolio a machine tailored to their needs and scale of operations.

Investment in HF technology is a step towards production professionalization, increased market competitiveness, and customer satisfaction receiving products of the highest quality.

FIAB Sp. z o.o. Bronisław Koziołkiewicz Sp. k.

Wrocław 54-615

ul. Rakietowa 38

POLAND

NIP 8942999829

KRS 0000357875

REGON 021278590

BDO 000072061

By sending the inquiry to sales@fiabmachines.com, info@fiabmachines.com you agree to process your personal data for marketing purpose. If you do not agree on that, please inform us via e-mail.

Copyright © 2025 FIAB Machines