HF Technology in Flexible Tank Production

FIAB high-frequency welding machines are an advanced solution for manufacturers of flexible tanks for liquids and gases. HF technology ensures hermetic, durable welds with parameters ensuring safe storage of liquid and gaseous substances for decades.

Applications of Flexible Tanks

Water Tanks

- Drinking water – storage and transport of water for domestic purposes

- Rainwater – ground tanks for rainwater retention

- Technical water – supply for construction sites, farms, plantations

- Fire water – mobile tanks for fire brigades

- Animal drinking water – supply for farms

- Irrigation – water storage for crop irrigation

Gas Tanks

- Biogas – membrane tanks for biogas plants (up to 20,000 m³)

- Biomethane – storage of purified biogas

- Double-membrane tanks – spherical structures with pressure regulation

- Tanks over fermenters – wet fermenter covers

Specialist Tanks

- Liquid fertilizers RSM – storage of UAN fertilizers

- Slurry and liquid manure – tanks for agricultural wastewater

- Oils and fuels – safe storage of petroleum products

- Wines and juices – food-grade tanks with certificates

- Flood barriers – water-filled structures

FIAB Models for Tank Manufacturers

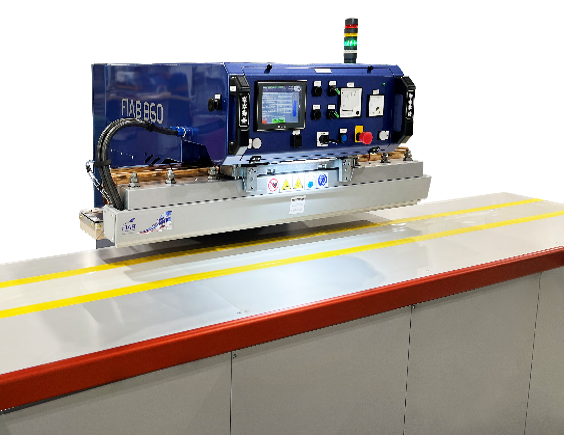

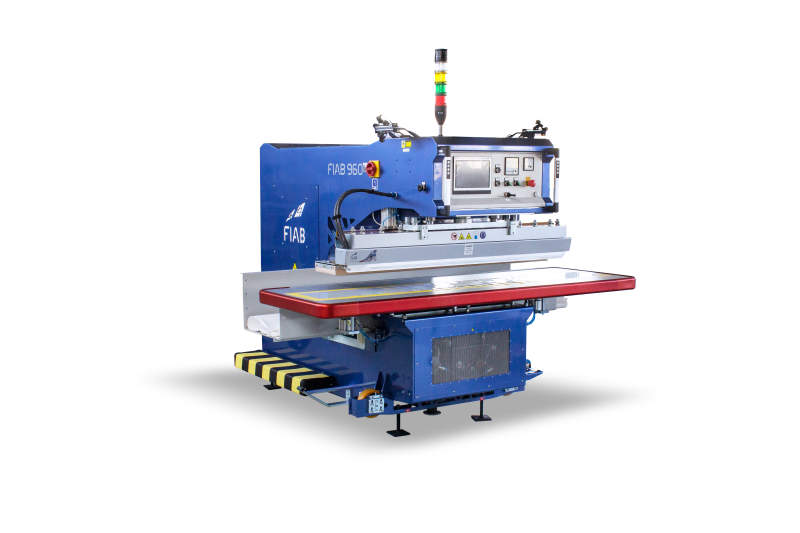

FIAB 500, 860, 960 (5-8 kW) – production of small and medium tanks (2,500-10,000 liters).

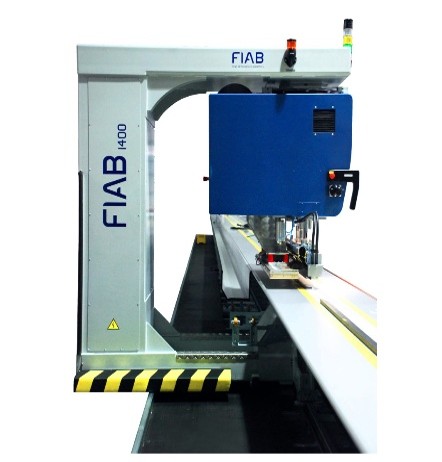

FIAB 1400 (13-26 kW) – industrial series with electrode up to 1500 mm for production of large-format tanks (10,000-100,000 liters). Mobile construction enables welding of panels 20-50m long.

FIAB 1900W, 2060W – machines for the largest industrial tanks (over 100,000 liters).

Tank Materials

- Coated PVC (900-1500 g/m²) – durable lacquered polyester fabrics

- PVC/PVDF – materials with UV protection for long-term operation

- Polyurethane (PU) – elastic, chemically resistant materials

- Multi-layer composites – polyester mesh + PVC coatings + UV filter

- Food-grade materials – certified for contact with food and drinking water

Properties of Flexible Tanks

- Tensile strength 4000-6000 N/5cm

- UV resistance – durability 25-30 years

- Tightness – 100% hermetic HF welds

- Flexibility – operating temperature -40°C to +70°C

- Chemical resistance – compatibility with liquids and gases

- Odorless – no plasticizer release

- PZH certificates – approved for drinking water

Flexible Tank Construction

- Main shell – welded panels from technical fabric

- Corner reinforcements – double layers at stress points

- Valves and fittings – application of filling/emptying valves

- Pressure connectors – fastening systems for gas tanks

- Fastening straps – handles for stabilization and transport

- Inspection openings – internal access for maintenance

Tank Production Process

- CAD design according to dimensions and capacity (2.5-1000 m³)

- CNC cutting of panels from technical fabric

- HF welding of panels into spatial structure

- Application of reinforcements in corners and fold lines

- Mounting valves, fittings, filters

- Tightness testing with air/water pressure

- Weld quality control

- Folding and packaging for transport

Advantages of HF Technology

- Absolute tightness – hermetic welds for liquids and gases

- Strength – welds stronger than base material

- Durability – resistance to UV, chemicals, microorganisms

- Safety – no emission of harmful substances

- Speed – production of 10-50 m³ tanks in 1-2 days

- Precision – parameter repeatability compliant with ISO

Standard Capacities

- Small: 2,500 - 10,000 liters

- Medium: 10,000 - 50,000 liters

- Large: 50,000 - 200,000 liters

- Industrial: 200,000 - 1,000,000 liters

Standards and Certificates

- PZH Certificate – approval for drinking water

- Food certificates – food contact

- GREENEVO – award from Ministry of Climate and Environment

- ISO 9001 – quality management system

- ATEX – for biogas tanks in explosive atmospheres

- Building standards – gas tank structures

Industry Applications

Agriculture

- Water storage for animals and crops

- Storage of liquid fertilizers

- Tanks for slurry and liquid manure

- Agricultural biogas plants

Construction

- Water supply for construction sites

- Storage of mortars and emulsions

- Technical and retention tanks

Industry

- Storage of liquid raw materials

- Process tanks

- Rainwater retention in plants

Energy

- Biogas tanks in biogas plants

- Biomethane storage

- Water retention systems

Military and Rescue

- Mobile field tanks

- Drinking water supply in the field

- Flood barriers

Production Efficiency

- Production of 5-20 tanks weekly (depending on size)

- Tank lifespan 25-30 years

- Mobility – foldable to 1/20 of working volume

- Weight 10-15% of traditional tank weight

Production Infrastructure

- Hall min. 30-100m length

- 3x400V power supply (32-63A)

- Welding tables or rail tracks

- Testing station with compressor

Advantages Over Traditional Tanks

- 50-70% lower investment costs

- No foundation costs

- Easy transport and assembly

- Relocatable

- No corrosion and cracks

- Aesthetics and no construction waste

FIAB welding machines are a professional solution for flexible tank manufacturers, ensuring tightness, durability, and safety of liquid and gas storage in accordance with the highest quality standards.