HF Technology for Membrane Architecture

FIAB high-frequency welding machines are an advanced solution for manufacturers of membrane structures and large-format canopies. HF technology ensures durable, sealed welds on architectural materials with areas reaching thousands of square meters.

Applications in Sports Architecture

- Stadium canopies – roof membranes over stands and sports arenas

- Football and athletics stadiums – stand covers with area of 500-5000 m²

- Tennis courts – year-round and retractable roofs

- Sports halls – tensioned structures over enclosed facilities

- Swimming pools and ice rinks – canopies for aquatic and ice facilities

- Amphitheaters – membranes over stages and auditoriums

- Orlik sports fields – covers for small sports facilities

- Retractable roofs – folding systems like at the National Stadium in Warsaw

Membrane Structures

- Low-pressure membranes – saddle and arch systems tensioned with cables

- High-pressure membranes – pneumatic structures and inflatable structures

- Stretch ceilings – internal covers for facilities

- Membrane facades – external walls made of architectural fabrics

FIAB Models for Large-Format Structures

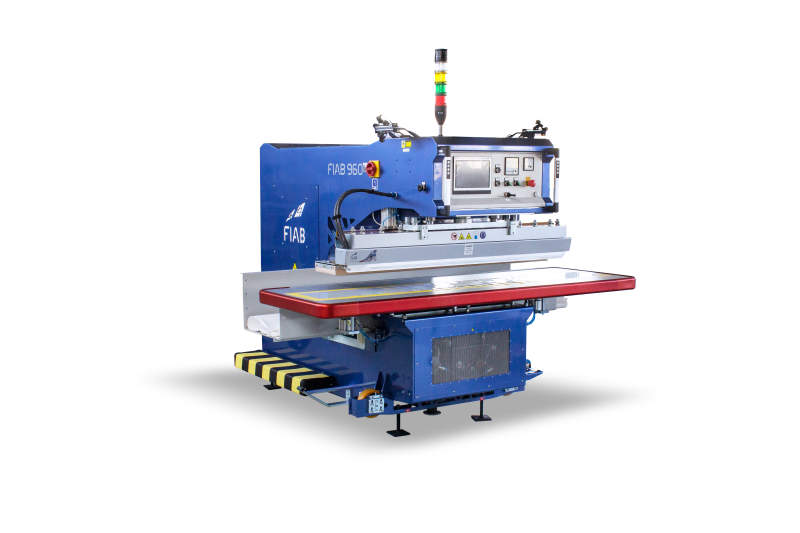

FIAB 960 – machine with 8 kW power and electrode up to 800 mm, ideal for medium sections of stadium membranes.

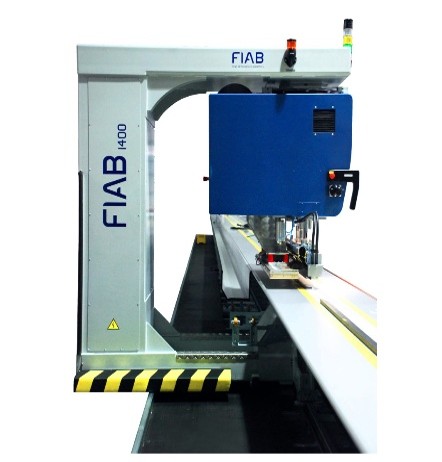

FIAB 1400 (13-26 kW) – premium series with electrode up to 1500 mm. Construction with the ability to work "from the inside" enables welding of large-format membrane panels. Available in stationary and rail-mounted mobile versions (up to 100m hall length).

FIAB 1900W and 2060W – machines with the largest working width for extremely wide membrane sections.

FIAB HPS-MINI – mobile 8 kW welding machine for repairs and on-site assembly.

Architectural Materials

- PVC/PVDF (900-1400 g/m²) – polyester fabric coated with PVC with PVDF protection (e.g., Mehatop, Valmex)

- PTFE – glass fiber coated with Teflon (National Stadium - 54,000 m²)

- Fluotop T2 – polyester fiber with protective layer for retractable roofs

- ETFE – architectural films for pneumatic cushions

Properties of Stadium Membranes

- Tensile strength above 5000 N/5cm

- UV resistance and weather conditions (25+ years lifespan)

- Fire resistance class M2 according to EN 13501-1

- Self-cleaning properties (PVDF coating)

- Natural light translucency

- Thermal resistance -40°C to +70°C

Stadium Membrane Production Process

- 3D design of membrane structure in CAD software

- Material compensation (consideration of tension and deformation)

- Cutting membrane sections with CNC plotters

- HF welding of sections into panels with area of 500-2000 m²

- Edge reinforcements and mounting of fastening piping

- Application of mounting elements (hooks, straps, rings)

- Weld quality and tightness control

- Packaging and transport to construction site

- Assembly and tensioning on steel structure

Advantages of HF Technology

- Strength – welds stronger than base material

- Tightness – hermetic connections resistant to leaks

- Aesthetics – smooth, even welds invisible from distance

- Speed – production of thousands of m² weekly

- Precision – adaptation to complex architectural shapes

- Durability – welds resistant to multi-year stress and tension

Requirements for Membrane Production

- Production hall minimum 25-100m length

- Welding tables or rail tracks

- 3x400V power supply (32-63A)

- Compressed air 6-7 bar

- Weld quality control system

- CAD software for membrane compensation

Specialist Electrodes

- Straight electrodes – linear welds of sections

- Curved electrodes – contour connections

- Reinforcing electrodes – double welds in critical areas

- Piping electrodes – application of cables and fastening elements

Standards and Norms

- EN 13501-1 – fire classification of building materials

- DIN 4102 – fire resistance standards

- REACH Directive – chemical substance safety

- Static and strength standards for structures

Implementation Examples

- EURO 2012 Arena Poznań – Mehatop F 1400 FR membrane

- National Stadium Warsaw – 54,000 m² PTFE + 10,000 m² PVC

- City stadiums – stand canopies 500-1500 m²

- Amphitheaters – membranes over stages

- Tennis courts – year-round roofs

Production Economics

- Production of 500-3000 m² of membrane weekly

- Canopy lifespan 25-30 years

- Low operating costs vs traditional structures

- Possibility of dismantling and relocating structures

FIAB welding machines are a professional tool for membrane structure manufacturers, enabling the realization of spectacular architectural projects with the highest strength and aesthetic parameters.